End Seals in Flexo Printing: Preventing Leaks and Ensuring Efficiency

In the world of flexographic printing, precision and efficiency aren’t just goals, they’re requirements. While doctor blades often take center stage in conversations about ink metering and print quality, there’s another unsung hero that plays a critical role in pressroom performance: end seals.

What Do End Seals Actually Do?

End seals are the components located at each end of the doctor blade chamber. Their job? Prevent ink from leaking out of the chamber while maintaining the right amount of pressure to allow smooth, consistent ink flow across the anilox roll. They’re essential in maintaining print consistency, minimizing mess, and reducing downtime.

Without properly functioning end seals, the results are immediate and costly: ink leaks, blade wear, increased downtime for cleanup, and potential press damage. In short, even the most advanced pressroom equipment can be undermined by subpar seals.

Common Challenges with End Seals

Even experienced printers face recurring issues with standard end seals:

- Ink leakage and splatter, especially at higher speeds

- Premature wear, leading to more frequent replacement cycles

- Inconsistent fit, especially with aftermarket seals that don’t match press specs

- Material degradation, especially when exposed to aggressive inks or solvents

When end seals underperform, they can compromise the entire print process. That’s why the design, material, and precision of these components matter more than many realize.

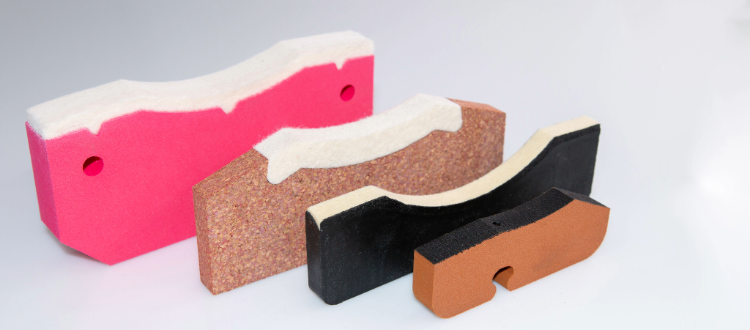

Provident’s AquaShear™ End Seals: Custom End Seal Solutions

Provident’s proprietary AquaShear™ end seals were engineered specifically to address, and eliminate, these challenges. Using a precision machining process unique to Provident, AquaShear™ technology delivers:

Cleaner, Leak-Free Seals

AquaShear™ ensures a perfect edge profile, eliminating ink bypass and reducing splatter, even at high press speeds.

Extended Durability

Made from high-performance materials like felt, foam, and custom composites, AquaShear™ seals last longer and resist deformation, meaning fewer changeouts and more uptime.

Custom Fit, Every Time

Forget generic die-cut seals. Every AquaShear™ seal is CAD-designed and digitally archived, ensuring a consistent, press-specific fit that optimizes chamber performance.

Faster Reordering and Press Recovery

Because designs are archived, repeat orders are quick and precise. No need for lengthy approvals or retooling.

Why Custom End Seals are Important

In flexo printing, details drive results. A leaking end seal isn’t just an annoyance, it’s a disruption. Provident’s AquaShear™ seals offer a smarter, more precise solution that aligns with what today’s printers need most: less downtime, more consistency, and no surprises on press.

Ready to Upgrade?

Let us show you how AquaShear™ can improve your bottom line. Request a sample or speak directly with a Provident pressroom expert to get started.