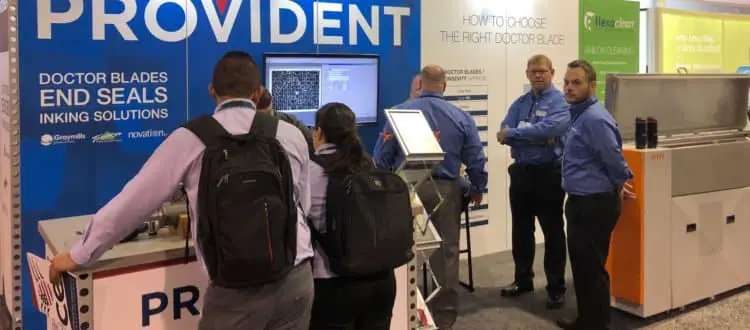

Blog

Flexo Industry Blog by Provident Group

Stay on top of flexo industry news and Provident product information by visiting the Provident Group blog.

Load More

Load More