The printing and packaging space is ever-evolving, with Consumer Packaged Goods (CPG) companies looking for new and innovative ways to showcase their brand across different printed mediums. To help them stand out in the saturated market, CPG brands want new printing capabilities and better quality for their packaged products.

A great example of this can be seen through an Amazon delivery box. For many years, Amazon could only use printed sealing tape on a plain brown box; however, with recent developments in the flexographic printing and packaging space, Amazon is now able to have branding printed on the box itself.

Many printing companies, wide and narrow web, have noticed this shift from their customers, and are starting to see this trend become a more frequent request. This specifically has created an opportunity for narrow web companies to capitalize on these projects by upgrading their current processes, but where should one start?

According to Andy Gillis, General Manager of Provident, “operators need to focus on the quality of their equipment and tools if they wish to deliver better and more efficient results.” For example, many of the ink delivery system designs are open (versus enclosed chambers) because press speeds are generally lower, but operators still need to meter the ink off the anilox roll to keep printed dots clean and color in spec. This is where quality doctor blades come in.

Upgrading Your Output with Doctor Blades

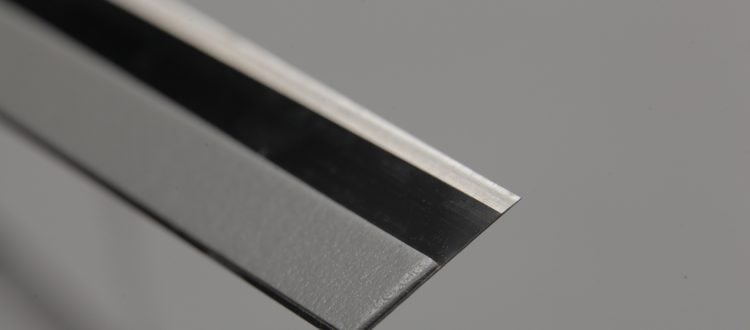

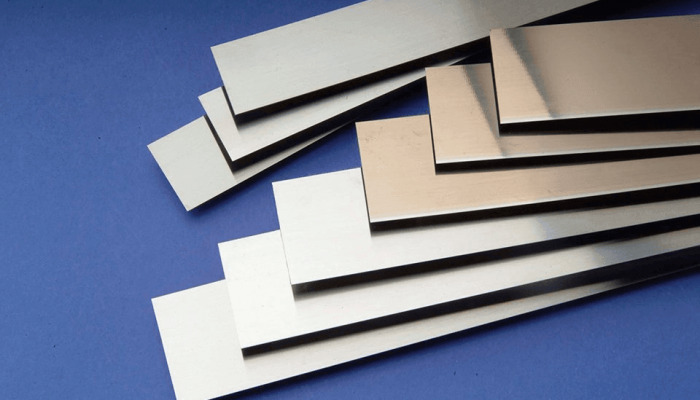

Doctor blades can make or break one’s output within printing. For example, more than 50% of the flexographic printing industry still uses a radius tip blade; but, what some companies don’t fully realize is that as the doctor blade wears, the contact area of the blade tip changes which can lead to challenges with dot gain and other print defects. This can lead to a cause-and-effect chain reaction to chasing problems, as operators will have to fight the variations in color by making adjustments on press i.e., adjusting viscosity, presenting more variability to those who are not as experienced. A higher-quality doctor blade with the proper tip selection would eliminate this extra work and provide operators with better predictability job after job. Additionally, doctor blades made from high-quality Swedish steel can last longer and have less wear on anilox rollers. With many material and tip options available, operators are sure to find the best type of blades for all their specific printing needs.

In the long run, using doctor blades matched for the print will allow operators to achieve more consistent and repeatable print. It is common for many companies to look at the savings of a unit price of a blade, but not understand they are hurting the operations by wasting time and material on press not having the right tool for the job. By using a job-specific, high-quality doctor blade, operators will not have to endure the short-term pains of blade wear and tip changes while better protecting their assets.

As mentioned earlier, graphics on packaging and labels have increased over the years and the fight for shelf space is fierce. Many companies are looking for designs that capture the consumer’s eye to promote their brand and create differentiation from their competition. Printers must figure out how to create better graphics effectively, within their own cost constraints. “There are a lot of variables to successful printing, and doctor blades are a key component in the heart of the press,” said Gillis. If one cannot effectively deliver ink at the film thickness that is required for the graphic capabilities of the job, then one cannot produce the best print that is desired. Without high-quality doctor blades, operators cannot print for either big or small companies, national or regional brands. Everyone wants their packaging to look as good as they can, no matter what the volume is, which is why it is a good idea for teams to invest in the best doctor blade for the job.

How a Partner in Narrow Web Efficiency Enhances Your Process

Every printer is looking to see where they can reduce waste. However, supply chain nightmares and price increases are very rampant in the flexographic printing industry. This means that the pace at which printers and operators improve internally must be greater than all the increases they are seeing within the industry. With this in mind, it is important to take a more tailored approach to every press operation. To find the right doctor blade for each press operation, narrow web operators should look into finding a partner who will help them find the best equipment for the specific job. Due to their slight differences, each doctor blade can greatly impact your press job, making it critical to engage with a partner who can understand the goals you are trying to achieve, the pain points you have, and the threshold between spending and performance.

Provident helps operators identify the type of doctor blade they need to deliver the best results by asking them the important questions and bridging the gap between office and client. By understanding each operator’s current setup, specific pain points, expectations for their presses, and their business goals, we work tirelessly with them so they can exceed expectations and achieve their desired results. “Everything in printing is cause and effect; we educate customers on what the root cause of their problem is and eliminate their corrective actions by providing them with high-quality doctor blades,” said Gillis.

Provident not only provides customers with the awareness that there is an extensive selection of higher-quality doctor blade options available on the market but also helps them match the right doctor blade with their specific application. As we develop custom-tailored technical solutions to enhance each press outfit, we can show operators how they can improve their operational and printing capabilities by using high-quality doctor blades that meter consistently from beginning to end, taking the guesswork out of their printing processes.

If you need assistance finding the right doctor blade for your press operations, contact Provident today.