Cleanliness is next to, well, quality, especially when it comes to your anilox rolls. We’ve talked before about the importance of having clean anilox rolls. Clean rolls save time, money, reduces substrate waste, and helps ensure the quality of every label or package you print. There are a number of approaches to ensuring your rolls are in the best possible condition. And, since there is no one-size-fits-all solution, it’s best to know your options and keep them open. Eaglewood Technologies, for instance, offers a variety of cleaning solutions that are perfect for your business. Today, we delve into Eaglewood’s high-tech option that puts the power of lasers to work on your shop floor.

In case you need to geek out…

Laser is an acronym for Light Amplification by Simulated Emission of Radiation. Varying the power and precisely focusing a light beam gives lasers the ability to do an amazing array of things. They can measure speed and distance, can be a pointer for presentations, and make some anti-intrusion systems tough to beat. Most importantly, they can both cut the cell patterns of your anilox rolls and clean out the dried ink that builds up in anilox cells and negatively affects the image quality of your presses.

Flexographic printers know their anilox rolls are important and are always asking us how to get the most life out of expensive anilox rolls. We offer several ways to measure cell capacity, including the Troika AniCAM, which provides the most information and the strongest tracking ability. But no matter which approach you choose, making sure your rolls are as clean as possible is the next step.

Success through sublimation

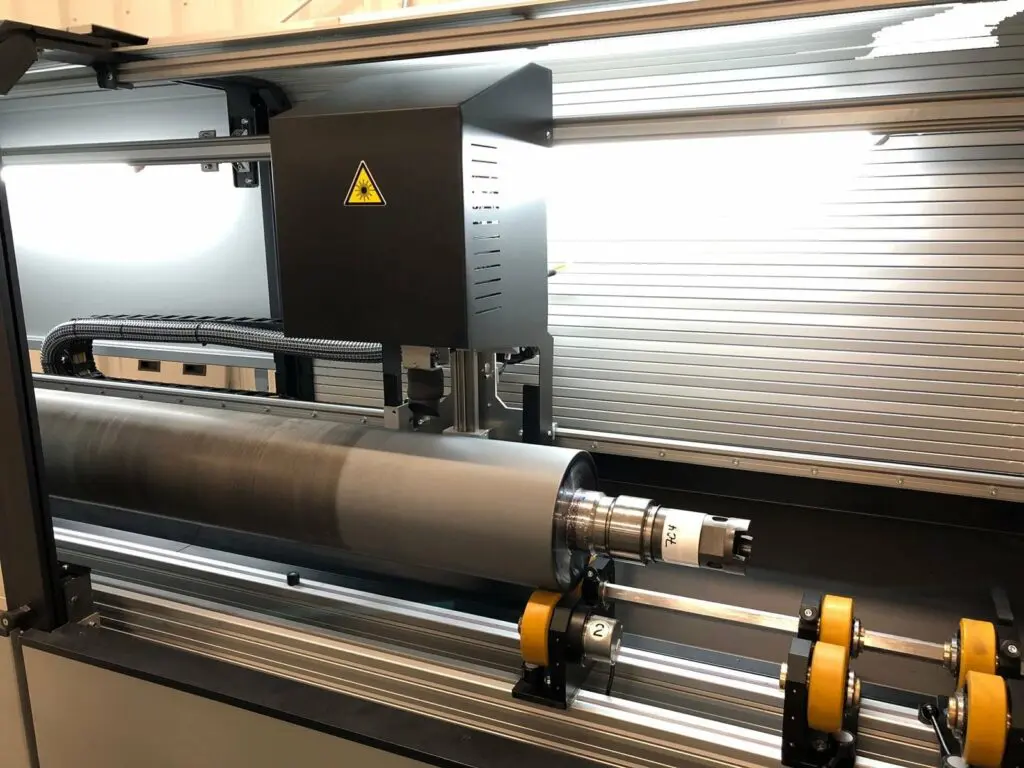

Laser cleaning, such as with the Sitexco Roll Cleaning System from Eaglewood Technologies, is a smart and effective way of maintaining your entire anilox inventory. It uses advanced laser technology and cutting-edge software to clean all types of ink and coating chemistries. Here’s how it works.

The laser heats the material which absorbs the laser energy and evaporates or sublimates the ink chemistry. Dried ink basically vanishes. Particles and residues such as adhesives and coatings that cannot be destroyed by the laser are removed from the surface and collected by the Sitexco extraction system. The laser beam is specifically designed to remove dried ink by pulsing the light at a specific rate and intensity. While often used on wide-web presses, the system is also well-suited for multiple narrow web rolls or a combination of narrow and wide web rolls and sleeves with one machine. Designed with flexographers’ businesses in mind the system features:

- Simple automated, touch-screen interface with recall for repeated jobs

- No line count limitations

- Cleaning of any ink type as well as adhesives, varnishes, and coatings

- Cleaning of anilox rolls, journals and anilox sleeves

- Zero damage or degradation to cells

- No water source needed

- Power usage of only 4 kw of power per hour (less than your household dishwasher)

- Interlocks that shut down the machine immediately if the safety guards are bypassed

We at Provident work with flexographers every day to help them make sure their presses and ink systems are in optimal condition so they can deliver the best possible print quality on every label and package they produce. Because we’ve seen every type of press and ink system maintenance process imaginable, we know what works and what causes problems immediately. We know that any shortcomings in anilox roll care and maintenance have a direct impact on your ability to provide the quality your customers expect. Reach out to us to learn more about how using anilox cleaning systems from Eaglewood Technologies can help ensure your rolls are always in the best possible condition and ready to deliver the quality your business stands for.