It’s probably not news to you that no doctor blade is right for every application. Still, I am constantly surprised by printers who call me in when their blades are being eaten alive by white or opaque inks.

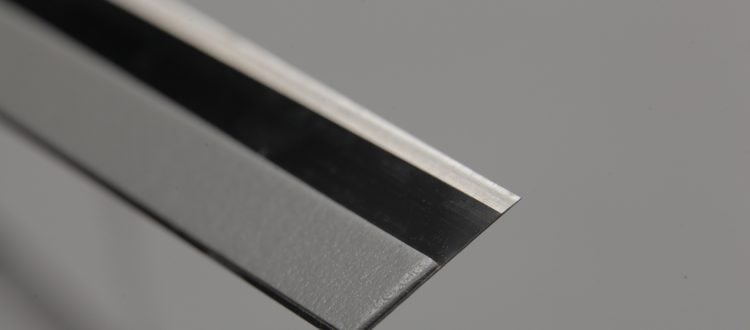

The popularity of film substrates these days has increased the use of white inks. Every one of them is made with titanium dioxide, which comes from minerals (rocks) that even when ground into a fine powder still have an appetite for the carbon steel of doctor blades, rapidly wearing them down and accelerating wear on your pricey anilox rolls. This shortcoming shows up fast on the job being printed. The solution is choosing blades designed to do their job of metering ink and of protecting your anilox rolls.

Lubrication

The correct blade is one that protects itself and your anilox rolls by gradually shedding an ablative coating that is engineered to combat the corrosive characteristics of titanium dioxide inks. The coating acts as a lubricant that mitigates the abrasive nature of the titanium inks to help blades last five to ten times longer than a typical carbon steel blade. Do they cost more? Yes, but their longer life means you are much less likely to find your press crew taking a press offline while they change blades. Presses only make money when they are running, so minimizing downtime increases productivity while limiting waste of inks, substrates and production time. Sure, you may only be running white ink on one station, but if the press needs to be stopped three or four times a day to change one blade the real cost of the cheaper blade is the combination of down time, wasted substrate, and ink, quickly exceeding the cost of a more durable blade. Then consider the life of an expensive anilox roll being shortened as the blade and white ink abrades the ceramic layer of the roll.

Specify Blades

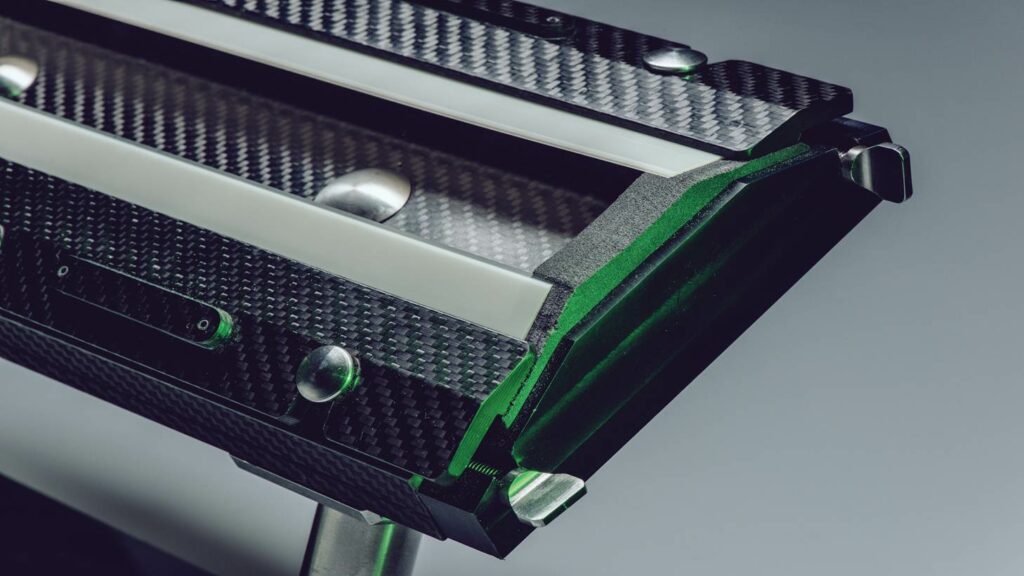

But white inks are not the only ones that wear blades faster. Opaque inks, metallics and coatings can also cause excessive wear to ordinary doctor blades. The upshot of this is that you need to make a practice of specifying the blades used on your flexo presses are based on job requirements. This is really Flexo Printing 101, but too many times I’ve found the solution to a problem is simply changing out the doctor blades. For instance, I was in one shop where the press operator had installed a durable blade for the white ink being used in the first station but had a very basic blade in the last station where a coating was being put over the entire label. The press was running fast and the doctor blade in that 7th station was having a very bad day. When I got there the press was stopping for the third time because the coating was just not being laid down very well. In that case we changed to a plastic blade and the problem was solved.

A plastic blade was also the solution in another shop that was having an ink spitting problem on a narrow web press with UV inks. This is not too unusual on UV presses because UV inks have a higher viscosity than water-based or solvent inks making them more prone to spitting. I suggested Esterlam plastic blades. We changed over all the blades, started the press back up and the spitting problem went away. The Esterlam blades, being a laminate of thinner plastics, are thicker than steel blades and can minimize or even eliminate spitting. Once again, it was a matter of using the right blades for the job at hand.

I could go on with a host of examples, but I’ll save some of those for the next blog. What makes this so interesting is that there is no single answer to the “which blade should I use?” question. But there are choices, and knowledge is your best resource. We at Provident Group are ink system experts and can help you make the best choices about blades, inks and end seals—three of your most important consumables. Never hesitate to contact us and we’ll respond as fast as we can.