“Label Expo 2018 was a fantastic event for Provident,” confirms Andy Gillis, General Manager of Provident Group. “There was a continuous stream of attendees at our booth, all very interested in our doctor blades, end seals and especially the Troika AniCam. It was an ideal opportunity to talk with printers and converters about the technologies we offer.”

A Closer Look at Anilox Rolls

Positioned at the entry to the booth, the Troika AniCam and its accompanying video drew a continuous flow of flexo press owners looking for ways of getting the most out of their pricey anilox rolls. Randy Carter, Provident’s Senior Technical Sales Rep, offered up a steady stream of presentations showing the level of detailed anilox roll analysis the AniCam can provide and how the device can help a shop get more value out of every anilox roll they buy.

As he talked, Mr. Carter highlighted three ways to make the best use of the AniCam:

- QC incoming anilox rolls to make sure a new roll will provide the resolution you expect.

- Ensure the various rolls you have in house are clean and damage-free

- Help measure the effectiveness of your present cleaning methods and identify any weak points in your present practices and equipment.

Next month, we’ll go into more detail about the AniCam and show the real world dollars and cents advantage this device can deliver for flexo shops. It’s all about providing insights and new knowledge about your press, helping you control costs and improve profitability.

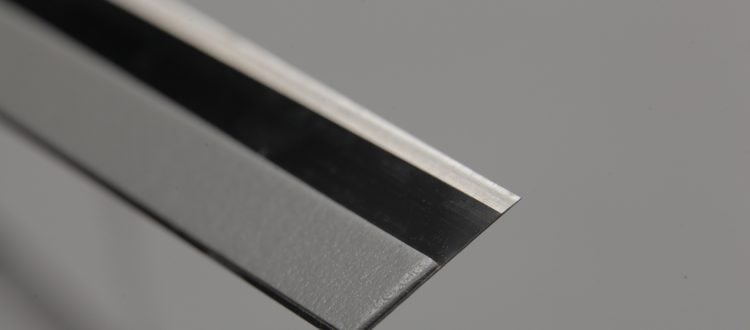

Blades & Seals

Mr. Gillis and his team took the opportunity at Labelexpo to share the benefits of one of the company’s latest offerings, laminated, non-metallic doctor blades from Esterlam. These blades are gaining a strong following from flexo shops around the world for overall performance, especially in shops that handle long runs of corrugated material and which may keep blades in place for as long as a month. Synthetic blades have long been an option for flexo shops but often needed frequent replacement—until laminated blades from Esterlam became available. And at Labelexpo Provident had a story to tell…and people were listening.

Provident also showed off its ability to provide end seals for just about every type of flexo press imaginable, using a mix of materials, and always delivering a custom fit that helps ensure seals will perform as required with much less risk of unexpected leaks and blow-outs that result in lost productivity. Provident’s end seals weren’t just impressing Labelexpo attendees: a few hundred feet away, press maker Nilpeter was using Provident’s end seals on one of its presses which were running had at the show, proving the value of the seals in a venue where failure was not an option.

Got questions?

As ink system experts, the Provident product team was on hand to answer any concerns and questions attendees had, help them solve problems, and find paths to better productivity. In addition, when a question was outside their expertise, attendees could be walked across the aisle and introduced to other product experts in the Anderson & Vreeland booth, enhancing the synergy between the two companies.

“This was the best Labelexpo we’ve had,” said Mr. Gillis. “We’ll be back when the show returns to the U.S. in 2020. We’ll have a much bigger booth with dedicated stations that focus on our specific areas of expertise. We are making sure flexo shops know Provident is a team of ink systems experts and that they can turn to us to get the most out of every part of their press.”