3D QC Analysis

Troika’s advanced inspection and database tools help printers maintain consistency, reduce waste, and improve control across flexo, gravure, and anilox applications.

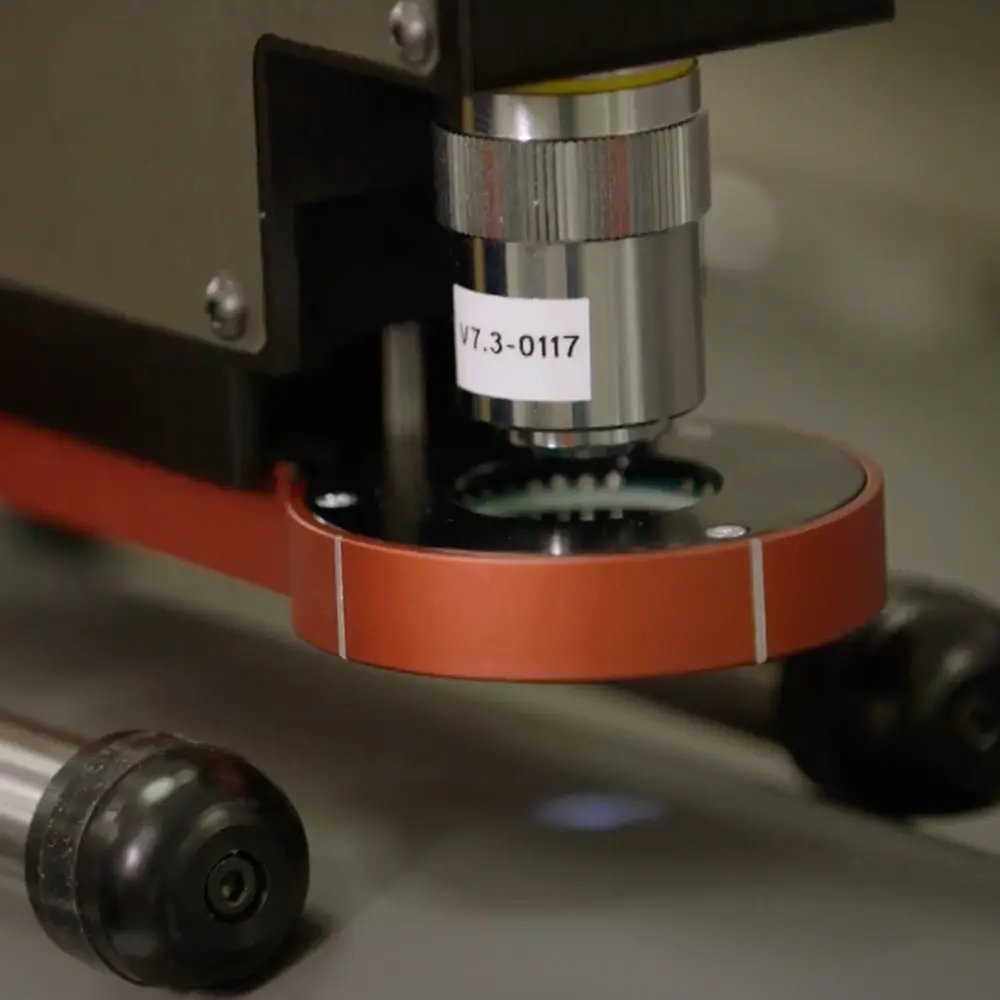

AniCAM HD Plus™

Troika’s flagship inspection device for measuring cell volume, screen count, wall structure, and overall condition of anilox rolls, gravure cylinders, and flexo plates, with micron-level accuracy and fast 3D scanning.

MagneCAM HD Plus™

A non-contact inspection solution for gravure cylinders, designed to deliver fast, accurate measurements without requiring mechanical contact, ideal for delicate or high-speed applications.

SurfaceCAM HD™

A specialized 3D surface analysis tool, widely used by engravers and prepress teams for detailed inspection of surface geometry, engraving quality, and wear.

Anilox & Cylinder Management Systems

Powerful software platforms for tracking roll history, managing maintenance, and optimizing inventory.

- Anilox Management System (AMS)

- Cylinder Management System

Provident Quality Control Analysis

Ensuring Top Quality — Every Time

Our customers rely on the best quality QC processes and tools to stay ahead of the competition. Learn more about Troika Systems’ hardware and software that uses the latest technology for more accurate, efficient printing.